What are the differences between zero-joint edgebanding and glue edgebanding?

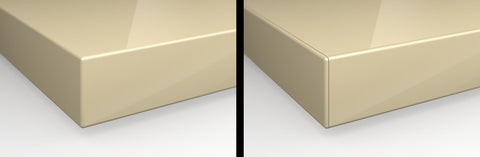

Glue edgebanding has a line on the edge of each panel with the ability to collect dirt and bacteria, chip away or yellow over time. However, with zero-joint edgebanding, it replaces the tradition glue with a pre-applied functional layer. This gives the look of a monolithic panel.

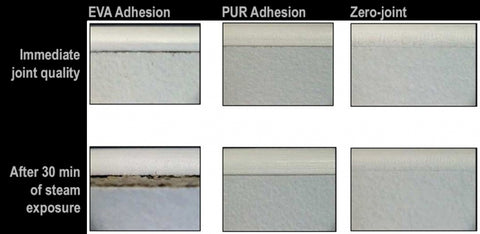

To say it simply, zero-joint edgebanding makes your millwork designs, seamless. To be more technical, this edgebanding is processed by melting a co-extruded polymer functional layer with a hot-air, laser, or NIR edgebander. Hot-air is a less expensive way of activating the functional layer when compared to a laser, while still creating that desired smooth edge joint. Whatever edgebanding you choose to put in your designs, you need to make sure it is heat and moisture resistant.

In a steam exposure test comparing the connection between the board and edgebanding with EVA adhesion, PUR adhesion and zero-joint, zero-joint didn’t split.

Make sure to look for a zero-joint edgebanding manufacturer with the ability to truly create a seamless edge with a co-extruded polymer functional layer. Not all layers are the same! There is no need to be on the edge of your seat, hoping you chose the right panel with the right edging. So, when you are looking to seal the perfect panel in your design, be sure to look for a zero-joint edgebanding option.

Article source: http://na.rehau-blog.com/modern-millwork-3-qualities-to-look-for-in-zero-joint-edgebanding/

About Woodworking Consumables